This easy and inexpensive shoe cabinet can be built in a matter of hours, and out of low-cost MDF. Stop with a simple build, or do what I did and take your router skills from zero to hero by adding fluting!

Well, I finished up cabinetmaking school last week and am officially a graduate!

Which is interesting seeing as I never made a single kitchen cabinet from start to finish?

I think the program should have been called furniture making, since that’s what I spent my time on.

Regardless, I was heading into my last week of classes and there were a few things that I still hadn’t tried/learned; I hadn’t worked with a single piece of MDF, and I needed to overcome my somewhat irrational fear of routers.

Enter The Maker’s Challenge 13 – which was happening at the same time – serendipitous!!

If you haven’t heard of The Maker’s Challenge – formerly the Builder’s Challenge – it is a building challenge for people of all skill levels to compete for a prize. Often the building plans are provided and the competition revolves around how to make it your own like with fine joinery, specialty woods, dramatic finishing techniques etc. It’s because of The Builder’s Challenge that I attempted my first large build of a DIY Media Console for my Dad several years back.

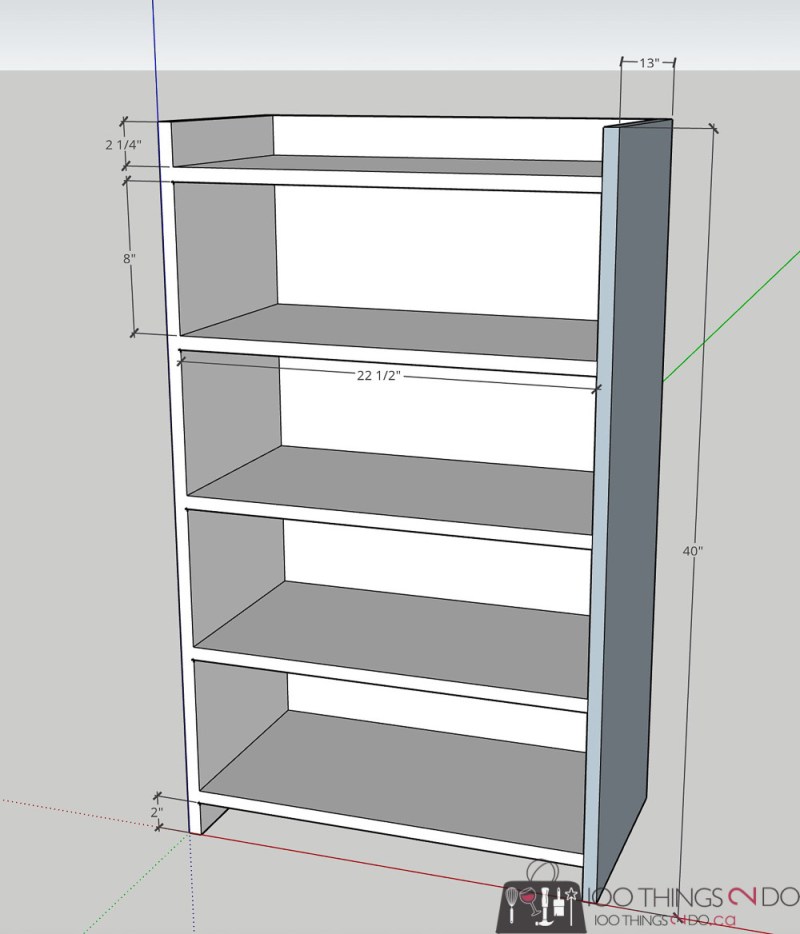

The challenge this time around was to build a shoe cabinet (or other entryway project) and plans for this were provided:

PERFECT timing for a house with a shoe-chewing-puppy!

But the building plans didn’t exactly meet what I wanted; for example, the cupboard door needed to go all the way to the bottom to protect ALL the shoes from puppy teeth. The cabinet in the plans only had shelves that were 10 ½” deep, but 12″ is more appropriate for adult-sized shoes.

I redrew the plans to fit my needs:

Each shelf is 12 ¼” deep.

I tried to fit all of the components onto one 4′ x 8′ sheet of wood, but fell slightly short with the second door panel. (so frustrating!)

Not enough to buy a full second sheet, but if you have any wood at 12″ wide by 36″ long you can use that, or purchase a half-sheet instead.

I chose to work with MDF to get some extra practice in working with this frustrating composite. In the past I’ve over-drilled and my screw holes seem to strip out, or I get bulges if I don’t pre-drill, or the wood swells with any mistakes in finishing. I have had almost no luck whatsoever with MDF.

This was the opportunity to learn the proper procedures and techniques!

First off – wear a mask! MDF is absolutely HORRIBLE for your lungs. Worse than any real wood product and the particles can do some pretty serious damage over time. Please wear your safety gear.

Using ¾” MDF, I used a panel saw to cut my pieces to size (a table saw is fine). Alternatively, some home improvement stores will do a few cuts for you to make the sheet easier to fit into your car.

Fluted Shoe Cabinet – cut list

(2) 13″ x 40″ doors

(1) 22 ½” x 40″ backing

(5) 22 ½” x 12 ¼” shelves

(2) 12″ x 35 ¾” doors

I used my Kreg Jig and drilled pocket holes into the two sides of the backing panel of the shoe cabinet, spacing them about every 6″.

Drill a couple of pocket holes on either end of your (5) shelf pieces as well.

I followed the Maker’s Challenge plans and added a bit of detailing by cutting a 45° angle on the upper, front corner of both side pieces and a bit of a foot cutout in the bottom of both sides. Nothing too fancy, and easily cut with a jigsaw.

Attach your backing to the inside of each side piece using wood glue and 1 ¼” pocket screws.

Because my shoe cabinet is sitting in an open space in my front hallway, the back will be visible. To hide the pocket holes without doing a lot of puttying, I opted to have them facing the inside of the cabinet instead of the outside.

I started by attaching my shelves from the top down; the uppermost shelf will line up with the bottom edge of your 45° cut on the sides.

From there I found that a 6″ shelf and (3) 8″ shelves made the best use of the space without finicky little measurements. I cut two 8″ spacers to make installing them easier and faster.

Attach each shelf with 1 ¼” pocket screws.

That’s a fairly basic cabinet and really – if you don’t have a hungry puppy – you could stop here and go right to finishing your shoe cupboard.

But I still wanted to gain some confidence with the router…

I found this image on Pinterest:

Yup – this shoe cabinet definitely needed some fluting detail!

I tested out fluting using a ½” roundover bit on a router table.

Router tables scare the shit out of me – an open blade that you are moving your hand past on a piece of wood that can (and has) shot back at me. Makes my ass clench thinking about it!

But, that’s where having a teacher around comes in handy; Kyran helped me set up the table so that I could make repetitive cuts with minimal risk.

We set up a fence on the router table and marked on it where the centre of the roundover bit was (pencil line). The fence was set at the centre point of the door panel (6″) – so your fluting will work from the centre out.

Then we set up two jigs to mark where we wanted the fluting to begin and to end – roughly 1″ in from either end of the door panel.

From here, with one jig down, I carefully lowered the door panel down onto the moving blade, then carefully lifted it back off. This will mark the end of your fluting.

Lift that jig up, lower the second and move to the opposite end of the door panel. Lower the MDF carefully onto the router blade and then slide your door along the fence until you reach the hole you initially drilled. Your pencil line will give you an idea of where to stop.

Lift the board off of the router blade (carefully) and shut off the router. You’ve cut your centre flute! Repeat on the second door panel before moving your fence.

I drew lines right on the router table at ½” increments. My following cuts were just a matter of lining up the fence with each of the markings.

For your remaining fluting cuts on your shoe cabinet, you will make two passes on each door panel; each will be ½” off from centre (or the last cut). Follow the instructions above – lowering one jig, cutting a hole, raising that marker and lowering the second to start the second hole, then drag the board until you feel the first hole or the wood lines up with the pencil line. Turn your door panel 180° and repeat.

Your fluting will move outwards from the centre column towards the sides and you can decide where and when to stop. I decided to finish up right around 1″ from the outside edges of the panels so that it would be roughly symmetrical to where the fluting stopped and started on the top and bottom of each door.

If you look closely you will see mistakes in my fluted shoe cabinet – but hey, no one is perfect on their first go-round right?

This was just what I needed to build a bit of confidence on the router table, and if I’m being honest, I LOVE the look of the fluting and will definitely be implementing it again on future builds.

Did you know that MDF comes pre-sanded to 150 grit? All that was left was a thorough sanding at 180 grit and 220 grit before a coat of primer.

I sanded with 320 grit after the primer set and then sprayed two coats (with dry time between) of Benjamin Moore Advance formula paint in Black Beauty.

Using a quality primer on MDF is IMPERATIVE! It’s the barrier that stops any moisture from expanding/swelling the wood, and gives a much smoother finish. Notice in the grooves where I didn’t prime and you can see that the finish isn’t as shiny or smooth.

Add your hinges and handles and you are done!

My home doesn’t have a closet in the front hall, so we just use this little coat rack. Once Bentley (our new puppy) arrived, the shoes sitting outside of the coat rack were fair game.

This little fluted shoe cabinet doesn’t take up much space, gives a bit of extra storage and while it’s not interior-designer-layout, it is functional and serves it’s purpose – so I’m pleased.

Depending on the size of your feet, you can fit between 8 and 12 pairs of shoes… more if you are looking to fit children’s shoes.

Of course we maxed it out immediately 😂

I like having the extra storage space on top to plop my purse and keep dog walking necessities on hand.

Outside of painting dry times, this fluted shoe cabinet took me two classes to make – and that included the extra time needed to set and learn how to manipulate the router and router table.

Not too shabby!

Have a great one!

Amazon Affiliate links: